सोमवार, 22 अगस्त 2016

रविवार, 21 अगस्त 2016

laptop battery charging circuit information

Analysis

of the laptop battery charging circuit

There are all kinds of laptop battery charging chip, but it can be divided into

two categories usually,first,is the old laptop battery charging chip used under the Intel 965 platform,

the representative mode l is MAX1772;second,is the new charging chip used above

Intel GM45 platform,uses SMBUS to transfer the charging instruction,the

representative model are ISL88731 and others.Next,analyze respectively the

working principle of two kinds of charging chip.Analysis of laptop battery charging chip

MAX1772

used usually under Intel 965GM platform

MAX1772 is the charger with high integration

density,low cost and more chemical battery brought out by Maxim company of

USA,it can form the battery charger with high precision and high efficiency by

taking advantage of it.MAX1772 also posses the function of the adapter

detection.MAX1772 has the following features:

|

| MAX1772 |

- Input current limit

- The precision of output voltage is about 0.7%;

- Can provide the charging current more than 4A;

- The efficiency has a maximum of 95%;

- The duty cycle has a maximum of 99.99%;

- The application range is wide,is suitable for Li+,NiCd,NiMH battery charging;

- The maximum battery voltage can reach to 8.2V;

- Low cost;

- The charging current and the charging voltage can be controlled by the analog input.

MAX1772 uses double row 28 pin packaging, the top view of the pin permutation is shown in figure 20-1.

- the power input pin

- the linear voltage.It makes the voltage input by DCIN pin to output 5.4V after being adjusted by the linear,during using,it should connect a shunt capacity with 1μF between this pin and the ground.

- the adapter current limit input

- 4.096V reference voltage output

- charge compensation capacitor connection

- the output current regulation loop compensation end

- voltage regulation loop compensation end

- analog ground

- analog ground

- the battery charging signal amplification output,when the working mode converts from the voltage model to the current mode,this end can be used to monitor and display the size of the charge current

- the adapter voltage detection

- AC detection output,is the open drain output form.When ACIN voltage is less than REF/2,this pin open drain outputs.

- the reference input

- the charging current control.The range of voltage is REFIN/32-REFIN.If its less than REFIN/55.the chip stops charging.

- the maximum output voltage setting input.The range of voltage is 0-REFIN.

- the battery serial number setting end,when this pin connects the ground,setstobe two series,when it connects LDO,sets to be four series,when it connects LDO/2,sets to be three series.

- the battery voltage output pin

- the output current detection input negative terminal

- the output current detection input positive terminal.Dur ng using,it should connect a current detection resistance between CSIN pin.

- the power ground

- down tube driving output end.This end connects with the G pole of the down tube

- the down tube drive power connecting termin l

- the power loop end of the top tube.This e d connects with the S pole of the top tube and the inductance.

- the top tube drive output end.Th s end connects with the G pole of the top tube.

- the top tube drive connection end.During using,it should connect a capacitance with 1μF between this pin and LX pin,

- the adapter current detection negative terminal

- the adapter current detection positive terminal

- the adapter input current monitor output

Application

circuit

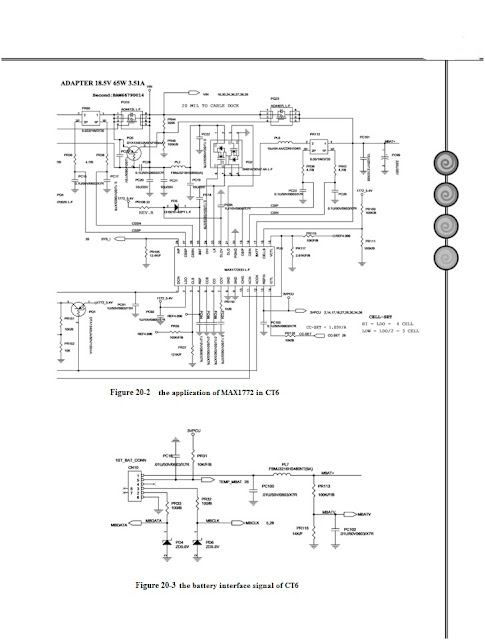

In this section, e mainly introduces the application of MAX1772 in

Quanta CT6,is shown in figure 20-2

The battery interface signal of CT6 is shown in figure 20-3,the

explanation of signal is below. MBDATA,MBCLK:the system management bus

data and clock.

TEMP_MBAT : Battery over temperature indicator. I consider : the main voltage of the Battery interface

MBATV:the battery voltage sampling

point,the sampling voltage is sent to EC,EC judges the fault.

The

working process:

MAX1772 through CELLS and VCTL sets the charging

voltage.EC through the system management bus reads the battery parameter,then

sends the charging current setting signal CC-SET to ICTL pin of the charging

chip,after MAX1772 receiving ICTL,starts to harge the battery according to the

set voltage and current,through charging current detection resistance to detect

the charging current.The setting of CELL pin is shown in figure 20-4,when the

voltage of CELLS pin is less than 0.2V,sets to be 2 core;when the voltage of

CELLS pin s h gher than 0.4V and is less than the voltage reduce 0.5V of LDO

pin,sets to be 3 core;when the voltage of CELLS is higher than the voltage

reduce 0.25V of LDO pin,sets to be 4 core.

The calculation of the charging

voltage:accordi g to the figure 20-2,we can know that CELLS is from the partial

pressure of 1772 5.4V,is set to be 3 core,REFIN is connected to

3VPCU(3.3V),VCTL gets 0.848V by the partial pressure of REF4.09.According to

the formula(20.1),we can calculate that t e c arging voltage is 12.6V.As the

following.

The calculation of the charging

current:in the figure 20-2,the charging current detection resistance PR112(is

RS2 in the formula(20.2) is 0.05W.According to the formula(20.2),it

only needs to change VICTL,then the charging current can be changed.

ICHG=VREF ´VICTL´ 1

RS2VREFIN 20

If VICTL

sent by EC is 1V voltage,then we can calculate that the charging current is

1.24A.

I

|

CHG

|

=

|

4.096

|

´

|

1

|

x

|

1

|

|

0.05

|

3.3

|

20

|

||||||

I

|

CHG

|

=

|

4.096 x

|

1

|

||||

3.3

|

||||||||

I

|

CHG

|

= 1.24

|

||||||

Analysis

of the charging chip ISL88731 used usually by the above Intel GM45

ISL88731 is the lithium ion

battery charger controller with highly integrated produced by Intersil company,

it can program through the system management bus. It is different from the traditional

charging chip,ISL88731 ough SMBUS communicates with EC to control

charging,SMBUS connects the battery interface, EC

and the charging chip at the same time.The charging voltage,charging current,

harging enable and other control signals are transmitted through SMBUS,no

VCTL,VICTL and other pins.ISL88731 has two functions of the adapter detection

and charging control.The main features of ISL88731:

0.5% battery voltage accuracy;

3%

charging current accuracy;

Battery

short circuit protection;

Quick

response pulse charging;

Rapid system load transient response;

Adapter

detection output,the adapter current monitor output;

The maximum battery charging current 8A;

The maximum current 11A of the adapter;

+8~+28V the range of the adapter voltage.

ISL88731 uses 28 pin TQFN packaging,5mm*5mm,the thickness is only

0.8mm.The top view of ISL88731 pin name is shown in figure 20-5.

The pin definition of ISL88731 is shown in table 20-2.

1

the vacant pin

2

AC adapter detection input

end.From the power adapter voltage dividing into voltage through two

resistances.

3

the reference voltage output,the standard value is

3.2V.

4

the charging current compensation point and the

adapter current regulation loop

5 the

vacant pin

6

the compensation point voltage regulation loop

7 the

vacant pin

8

inputs the current detection

output,the voltage of ICM is equal to 20 times of (VCSSP_VCSSN)

9

the system management bus

10

the system management bus

11

the system management bus module

power supply

12

ground connection

13

the adapter detection output.When

ACIN is higher th n 3.2V,ACOK signal open drain outputs the high level,needs

for external pulling up.

14

the vacant pin

15

the battery voltage feedback

16

the vacant pin

17

the charging current dete tion

negative input terminal

18

the charging current detection

positive input terminal

19

ground connection

20

the G pole driver signal of the charging down tube

21

the linear voltage of 5.2V output

22

the main power supply input

23

the phase pin,the top tube

driving loop

24

the G pole driver signal of the charging top tube

25

boot-strap send,supplies power to the driver of the

top tube

26

internal artificial circuit power supply,through

4.7W resistance connects VCC with

VDDP

27

the adapter current detection

negative input end

28the adapter current detection

positive input end.

The

typical application of ISL88731is shown in figure 20-6.

In the figure 20-6:the explanation of the working process of ISL88731

:

① After

the adapter switching in,and through the body diode sends to DCIN pin,supplies

main power to the chip;at the same time,through the resista ce dividing into

voltage sends to ACIN pin.

②The chip internal linear regulator block outputs

5.2V linear voltage from the chip VDDP,and through the resistance supplies the

main power supply to VCC.

③The chip internal produ es the reference voltage

with 3.2V.

④ After ACIN being higher than 3.2V,the chip open

drain outputs ACOK,is pulled up to be high level by VCC.

⑤ HOST(EC)

through SCL,SDA communicate with the battery interface,when the battery is low,EC through

SDA,SCL transmits the charging voltage,the charging current,the charging enable

and other control instruction to ISL88731.

⑥ The chip starts to drive the charging top tube and

down tube conducted in turn,outputs the voltage to charge the battery.

⑦ ISL88731 through VFB monitors the charging

voltage,through CSOP and CSON monitors the

⑧ The chip

through CSSP and CSSN monitors the current RS1 flows,that is the adapter

current.Enlarge the value of “CSSP-CSSN”20 times through the chip internal,and

outputs from ICM to send to EC,informs EC the size of the complete machine

input current at present.

⑨According

to the power dissipation of the total power of the adapter and the system

peration currently,EC adjusts the size of the charging current properly,to

prevent that the charging p wer is too high and exceeds the adapter output

limiting,then it will cause the adapter burning because of overload.